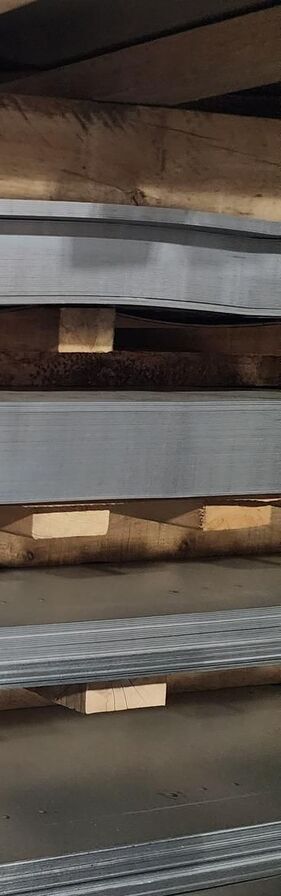

Aluminium transformation

Discover Aluminum: History, Applications, Properties, Economic Role and more. Usinage Laurentides has been processing aluminum for over 30 years.

Properties of aluminum

- Lightness : Aluminum reduces the weight of end products, which allows for better energy efficiency, greater payload and better performance in industries such as automotive and aerospace.

- Corrosion Resistance : Aluminum resists corrosion, providing increased durability, reduced maintenance costs and longer life in corrosive environments.

- Thermal and Electrical Conductivity : Aluminum is an excellent thermal and electrical conductor, used in electronic heat sinks and electrical cables for efficient and reliable operation.

- Durability : Aluminum is durable and recyclable, providing long product life, long-term savings and reduced environmental impact through recycling.

Find out how aluminum protects and enhances various industrial sectors

- Construction: Aluminum is used for windows, doors, facade cladding and lightweight structures in the construction industry due to its resistance to corrosion in the face of weathering.

- Transportation: Aluminum is used in the automotive and marine industry for bodies, panels, structures and components due to its corrosion resistance and light weight.

- Packaging: Aluminum is used in food and pharmaceutical packaging to create protective barriers against moisture, light and oxygen due to its resistance to corrosion.

- Electronic equipment: Aluminum is used in the manufacture of electronic devices such as laptops and smartphones due to its resistance to corrosion in humid environments.

Aluminum is an eco-responsible choice

- Durability : Aluminum is durable, corrosion resistant, strong and lightweight. It provides long life and reduces the need for frequent replacement.

- Recycling : Aluminum is 100% recyclable and can be recycled repeatedly without losing its essential properties. Recycling aluminum requires less energy than production from raw materials.

- Circular economy : Aluminum promotes a circular economy by being collected, sorted and recycled to create new products, reducing resource waste and reliance on virgin raw materials.

Aluminum in the modern world

Aluminum is the most widely used non-ferrous metal in the world. Its lightness, resistance and conductivity make it an essential element in many applications. From the 20th century, aluminum grew in popularity and was widely used in many sectors of the economy:

- The automobile

- aerospace

- electronics

- building

Transformation experts

Other metal processing processes

CNC cutting

Entrust your custom metal cutting to Usinage Laurentides. Take advantage of our personalized service to obtain metal parts exactly to your specifications. With our expertise and state-of-the-art equipment, we guarantee high-quality results to meet your specific needs.

- Laser cutting

- Digital cutting (CNC)

- Hallmark

- Stamping

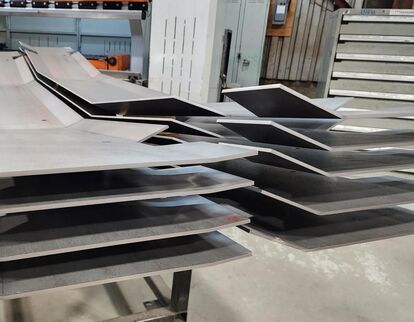

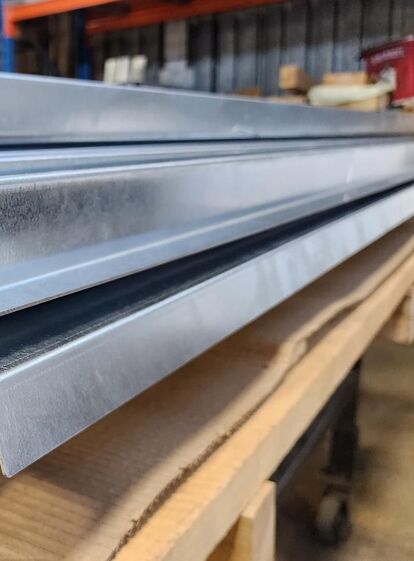

CNC bending

Usinage Laurentides puts at your disposal its latest generation bending machines and its 30 years of experience in bending and folding metal. Obtain high-quality finished products or metal parts for assembly that require complex bending processes.

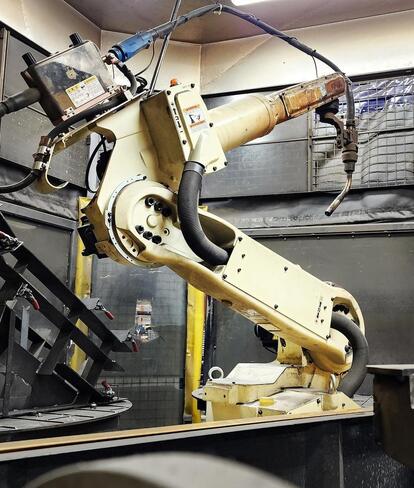

Robotic, spot and manual welding

Attentive to your needs, we adjust to your realities. We offer you custom manufacturing and production models in short, medium and large series thanks to the commitment of our teams and our passion for surpassing ourselves, constantly motivated by innovation.

- 6-axis robotic welding

- Manual welding

- Spot welding

Assembly of metal parts

Engineering ensures they understand the requirements of your original drawings, the factory produces for you while you attend to other tasks.

- Mechanically welded assembly

- Riveting

- Collage

- Bolting

Surface finishing and treatment

Whether the finishing is carried out at our factories or at our partners, you are assured that we will have the quality of everything that comes back to you. Our integrated service offering accelerates processing time while ensuring quality control from A to Z.

- Grinding and sandblasting

- Surface preparation

- Powder painting and electroplating (E-coat)

- Veneer and epoxy primer