Metal processing

Usinage Laurentides has been transforming metal for over 30 years. We meet your specific needs by transforming high quality, durable and resistant metal parts.

CNC cutting

Entrust your metal cutting to Usinage Laurentides. Take advantage of our personalized service to obtain metal parts exactly to your specifications. With our expertise and state-of-the-art equipment, we guarantee high-quality results to meet your specific needs.

- Laser cutting

- Digital cutting (CNC)

- Hallmark

- Stamping

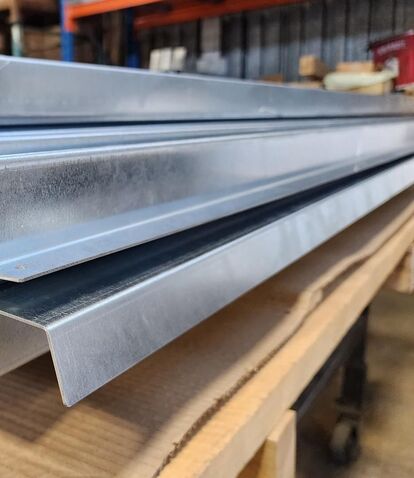

CNC bending

Usinage Laurentides puts at your disposal its latest generation bending machines and its 30 years of experience in bending and folding metal. Obtain high-quality finished products or metal parts for assembly that require complex bending processes.

Robotic, spot and manual welding

Attentive to your needs, we adjust to your realities. We offer you manufacturing models and production in short, medium and large series thanks to the commitment of our teams and our passion for surpassing ourselves, constantly motivated by innovation.

- 6-axis robotic welding

- Manual welding

- Spot welding

Assembly of metal parts

L’ingénierie s’assurent de bien saisir les exigences de vos dessins originaux, l’usine produit pour vous pendant que vous vous afférez à d’autres tâches.

- Assemblage mécano-soudé

- Rivetage

- Collage

- Boulonnage

Finishing and surface treatment

Whether the finishing is carried out at our factories or at our partners, you are assured that we will have the quality of everything that comes back to you. Our integrated service offering accelerates processing time while ensuring quality control from A to Z.

- Grinding and sandblasting

- Surface preparation

- Powder painting and electroplating (E-coat)

- Veneer and epoxy primer

Prospects for metal processing

Metal processing plays a vital role in many industrial fields, providing benefits such as strength, durability and precision. With advances in technology, new opportunities and challenges arise in the metal processing sector.

Innovation continues to revolutionize the techniques and materials used, opening up new perspectives for the manufacture of metal parts. The adoption of new technologies such as metal 3D printing allows for increased customization and more efficient manufacturing.