Metal processing

Stamping of metal parts

Benefit from our expertise in stamping metal parts. Usinage Laurentides prints and manufactures ready-to-assemble metal parts and finished metal products of superior quality.

Sheet Metal stamping process advantages

Sheet Metal stamping cost Efficiency

Sheet metal stamping process is a cost-effective manufacturing process for your project requirements, as it allows for high-speed, high-volume production with minimal material waste. This efficiency can result in lower production costs compared to other methods.

Sheet metal stamping precision and Consistency

Metal stamping process offers exceptional precision and consistency in producing complex, tight-tolerance components. This is crucial for industries like automotive and electronics, where parts must meet strict quality standards.

Sheet metal stamping speed and Efficiency

Metal stamping process machines can operate at high speeds, enabling rapid production of parts. This efficiency is particularly valuable when you need large quantities of components within tight timelines.

Material Versatility

Sheet metal stamping process can be used with a wide range of materials, including stainless steel, aluminum, copper, and more. Metal stamping services can also offer desired shape and desired form, using flat sheet metal and others, intricate shapes, can held tight tolerances and it has corrosion resistance. This versatility allows for the production of parts suitable for various applications across industries.

Durability and Strength

Stamped metal stamping components tend to be durable and exhibit for complex parts, excellent strength characteristics. This makes them suitable for applications that require parts to withstand significant stress, such as structural components in construction or automotive parts.

Stamping metal parts for manufacturing process

Health sector

Manufacture of complex metal stamping parts and sheet metal for the assembly of desired shape medical products and devices for the health sector.

Transport and heavy vehicle

We manufacture parts for transport and heavy vehicle desired shape components of all categories including bodywork, interior, access components, fasteners and more.

- Heavy vehicles

- Collection vehicles

- Mobility vehicles

- Electric vehicles

Sign and signaling sector

Manufacture of finished products and complex metal stamping parts intended for assembly for desired shape sign and signaling sector.

- Road sign

- Commercial display

Usinage Laurentides

Your manufacturing partner of excellence

Modern equipment combining speed and precision

Our latest generation equipment combines precision and speed to produce consistent high quality results:

Engineering, design and product development

We support manufacturers and agencies specializing in industrial design in prototyping, sourcing and manufacturing innovative products to solve today's challenges.

- Product research and development (R&D)

- Partner agencies in industrial design

- Prototyping and small series

- Optimization of technical drawings (3D and 2D)

Manufacture of complex metal parts and products

Benefit from the efficiency of work methods developed by solving the industrial challenges of our customers for more than 30 years.

- Medium/large series

- Finished metal products

- Parts intended for assembly

- Complex/unconventional parts

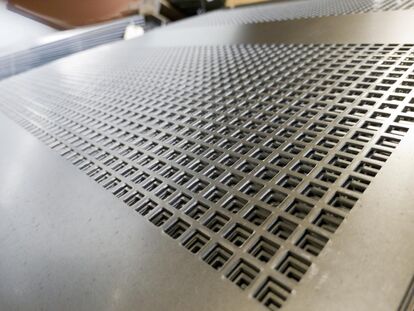

Sheet metal processing

Turnkey solutions for your steel and aluminum sheet processing needs.

- Steel, prepainted, stucco, aluminum & stainless steel

- Complex mechanically welded assemblies

- Numerically controlled cutting (CNC)

- Punching and punch/laser combo

- High precision machining

- Bending metal sheets

- Finishing and surface treatment

- Robotic, spot and manual welding

Visual inspection by critical points and rigorous quality control

From the review of technical drawings to the inspection of parts between our departments, we ensure compliance with established criteria to ensure the delivery of finished products and durable metal parts.

- Validation of technical drawings before production

- Visual inspection of parts at critical points

- Updating a register of irregularities

- Production of non-conformity reports (NCR)

Continuous supply of production materials

Driven by innovation and continuous improvement, we have given ourselves the mission of constantly reinventing ourselves; so as to become the sole partner of choice for manufacturers of value-added products from here and elsewhere.

- Continuous supply

- Inventory management

- International import and export

- Supply chain optimization

- Just-In-Time Approach

Electrical sector

From prototyping to mass production, we manufacture metal parts for products in the electrical industry and clean technologies.

- Electric charging stations

- Industrial transformers

- Battery components

- Electric vehicles

Transport and heavy vehicles

We manufacture parts for transport and heavy vehicle components of all categories including bodywork, interior, access components, fasteners and more.

- Heavy vehicles

- Emergency and leisure vehicles

- Collection vehicles

- Mobility vehicles

- Electric vehicles

Signage

Manufacture of finished products and complex metal parts intended for assembly for the sign and signaling sector.

- Road sign

- Commercial display

Entertainment and fun

Manufacture of finished products and complex metal parts intended for assembly for products in the entertainment and amusement sector.

HVAC

Manufacture of finished products and complex metal parts intended for assembly for the HVAC sector.

- Components of ventilation systems

- Heating system components

- Components of air conditioning systems

Furnishing

Manufacture of finished products and complex metal parts intended for assembly for products in the furniture sector.

- Displays

- Fixtures

- Commercial furniture

Health and medical

Manufacture of complex metal parts for the assembly of medical products and devices for the health sector.

Experts en transformation

Other metal transformation processes

CNC cutting

Entrust your custom metal cutting to Usinage Laurentides. Take advantage of our personalized service to obtain metal parts exactly according to your specifications. With our expertise and state-of-the-art equipment, we guarantee high quality results to meet your specific needs.

- Laser cut

- Digital cutting (CNC)

- Hallmark

- Stamping

CNC machine tool

CNC bending

Usinage Laurentides puts at your disposal its latest generation bending machines and its 30 years of experience in metal bending and bending. Obtain high quality finished products or metal parts for assembly that require complex bending processes.

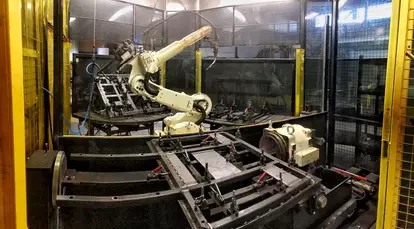

Robotic, spot and manual welding

Attentive to your needs, we adjust to your realities. We offer you models for custom manufacturing and production in short, medium and large series thanks to the commitment of our teams and our passion for excellence, constantly motivated by innovation.

- 6-axis robotic welding

- Manual welding

- Spot welding

Assembly of metal parts

Engineering makes sure to understand the requirements of your original drawings, the factory produces for you while you take care of other tasks.

- Mechanically welded assembly

- Riveting

- Bonding

- Bolting

Finish and surface treatment

Whether the finishing is done at our factories or at our partners, you are assured that we will have the quality of everything that comes back to you. Our integrated service offering accelerates processing time while ensuring quality control from A to Z.

- Grinding and sandblasting

- Surface preparation

- Powder coating and electroplating (E-coat)

- Plating and epoxy primer